clipspoly@gmail.com View Mobile Number

- Send SMS Send Email

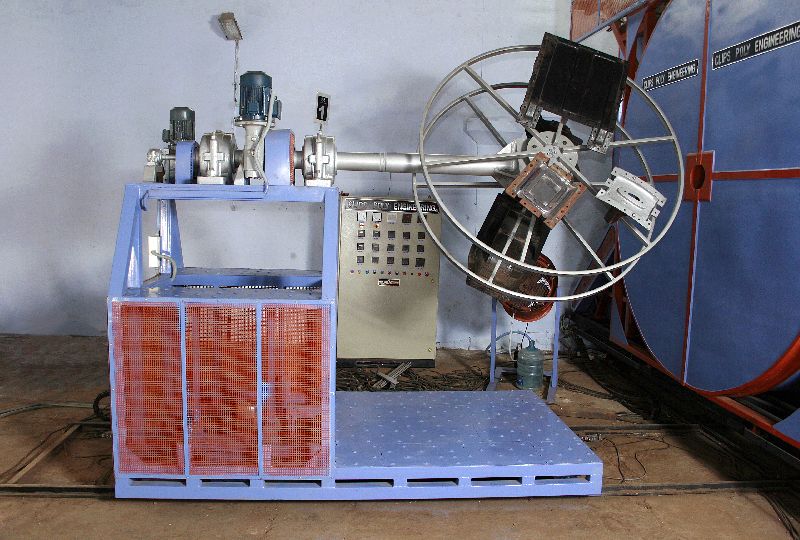

Rotomolding Machine

Leading Manufacturers, Exporters, Wholesaler and Retailer of Rotomoulding Machine, Independent Carousal Machine, Shuttle Type Rotomoulding Machine, Fixed Turret Carousel Rotomoulding Machine and Rock-N-Roll Rotomolding Machines from Faridabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Biaxial Rotomoulding Machine |

| Certification | CE Certified |

| Application | Producing Water Tanks |

| Driven Type | Electric |

| Country of Origin | India |

| Brand Name | CLIPS |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Weight | 100-1000kg |

| Voltage | 110V |

| Capacity | 500 mm Swing x 6300 mm |

| Warranty | 1year |

| Advantage | Easy operation |

Preferred Buyer From

| Location | Anywhere in India |

The Rotomoulding Plant with Independent Arm Carousel Machine � Series TSC is composed of Moulding Chamber (Stationary) with attatched combustion chamber, Cooling chamber with fog head, Central column and six stations track for conveyors movement, Arms conveyors & Control Electric Panel.

Salient Features

- Fastest heating and cooling times in the world industry

- Heavy-duty construction equipment that works from generation to generation

- Maintenance free machine

- User-friendly operations

- Reliable and consistent performance

- Jerk free movements

- Long service life

- Online support

- The floor area provides five to six station arrangements

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | Producing Water Tanks |

| Voltage | 380V-440V |

| Condition | New |

| Warranty | 1year |

Preferred Buyer From

| Location | Anywhere in India |

The Rotomoulding Plant with Multi Arm Shuttle machine Series CP is composed of Moulding Chamber ( Indexing )with attatched combustion chamber , High Velocity cooling fans with Fog heads , Arms conveyors .& Control Electric Panel. Shuttle Type Rotomoulding Machine is easy to install and promises optimum performance at low operating cost. Salient Features Aerodynamic Oven Designed for maximum hot air impingement against the molds and feature counter-convection air flow to help even heating throughout the chamber area. Moulding chamber made of metallic double wall frame, thermically insulated with high density rock wool. Burner (two stage) placed at the combustion chamber, heats the whole moulding chamber uniformly and keeps steady the process temperature recordings performed by thermic feelers installed in the moulding chamber. Centrifugal Fans with duct and louvers for adjusting hot air direction for correct distribution of the material inside the mould . Independent high velocity blowing fans for each Arm mounted on steel frame for uniform cooling. Turret made of heavy-duty steel tube construction Smooth conveyor movement on straight track. Floor area provides two process stations.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Weight | 1000-2000kg, 2000-3000kg, 3000-4000kg |

| Voltage | 110V, 380V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 1-3kw, 3-6kw, 9-12kw |

| Driven Type | Electric |

| Warranty | 5years |

Preferred Buyer From

| Location | Anywhere in India |

The Rotomoulding Plant with Fixed Turret Arm Machine � Series FTC is composed of Moulding Chamber ( Stationary )with attatched combustion chamber , Cooling chamber with fog heads , Central column and three stations track for conveyors movement & Control Electric Panel. Fixed Turret Carousel Rotomoulding Machine is designed for precise performance at minimum operating cost. Our valued customers can avail Fixed Turret Carousel Rotomoulding Machine in different specifications.

Salient Features

- Moulding chamber made of metallic double wall frame, thermically insulated with high-density rock wool at high acoustic values.

- Uniform process temperature of molding chamber ensures high quality product.

- Centrifugal Fans with duct and louvers for adjusting hot air direction for correct distribution of the material inside the mould.

- Cooling chamber made of steel frame with stainless steel water collection tub.

- Two high velocity-blowing fans with fog heads ensure uniform product cooling.

- Turret with multiple arms having strong construction

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Weight | 1000-1500kg, 1500-2000kg |

| Condition | New |

| Automatic Grade | Automatic Grade(Automatic |

| Power | 1-3kw, 12-15kw, 6-9kw, 9-12kw |

| Driven Type | Electric |

| Warranty | 5years |

Preferred Buyer From

| Location | Anywhere in India |

The Rotomoulding Plant with Rock & Roll machine� Series BS is composed of Heavy Duty Moulding Chamber with multiple burners placed strategically at bottom with Separate cooling station with high velocity cooling fans with Fogheads & Control Electric Panel.

Salient Features

- Sturdy machine suitable for manufacturing large size hollow products up to 40,000 ltrs or more

- Less investment, high production machine

- Multiple layer product can be made on this machine.

Speed variable drive for better Rocking & Rolling for better control of the product